- Why ULC?

- R&D Services

Research & Development

Leading Innovation. Driving Results.

- Industries

X-ID CROSS BORE DETECTION SERVICES

Our patented acoustic technology detects cross bores from within gas mains and services. Learn MoreLIVE GAS MAIN INSPECTION

We are leaders in the deployment of camera and crawler systems into live gas mains. Learn More

PORTABLE EMISSIONS RECOVERY

Our drawdown compressor technology helps gas distribution utilities reduce emissions. Learn More

AIM: AI-POWERED UTILITY MAPPING

Using vehicle-mounted cameras along with AI and Machine Learning to map electric distribution poles and pole-mounted assets. Learn More

CIRCUIT BREAKER RACKING ROBOT

Breaker Racking RobotAutonomous mobile robot designed to rack and unrack large breakers within substations. Learn More

ELECTRIC CONDUIT INSPECTION

Our field service teams provide video inspection of conduits prior to cable pulls to identify obstructions and pinpoint damages. Learn More

Machine Learning for Jacket Foundation Inspection

ULC used machine learning to enable more efficient inspection of jacket foundations at the Block Island Wind Farm. Learn More

Electrical Conduit Inspection Services

Our field teams provide internal inspection of conduits to pinpoint obstruction and damage prior to cable pulls. Learn More

Robotics & Technology Development

We work with leading energy companies to develop, commercialize, and deploy robotic systems and technologies that support the construction, maintenance, and inspection of infrastructure. Learn More

- Products & Services

Field Services

Products

Live Gas Main Inspection Cameras

Emissions Recovery

- Company

Circuit Breaker Racking Robot

Home > Technologies > Breaker Racking Robot

circuit Breaker Racking Robot

Empowering the Future of Substations with Safer Breaker Handling

ULC Technologies and Con Edison are developing a semi-autonomous mobile robot designed to rack medium voltage circuit breakers within indoor electric distribution substations. This innovative robot is set to revolutionize field fault locating, repair, restoration activities, and circuit breaker maintenance procedures, significantly enhancing efficiency and safety.

Close proximity to breakers during the racking in and racking out process can expose workers to arc flash. Additionally, manual handling of heavy circuit breakers can also lead to soft tissue injuries. Through remote-controlled driving and autonomous operations, the Breaker Racking Robot will carry out end-to-end breaker racking and storage to improve worker safety.

Key Benefits

Improve Operator Safety

Autonomously racking in and removing breakers from cubicles to ensure operators remain at a safe distance and prevent exposure to potential arc flashes. Also eliminates the need for physical labor by effortlessly maneuvering heavy breakers.

Obstacle Detection and Collision Avoidance

Equipped with two 2D LiDAR units, the robot can detect obstacles during navigation. If an obstacle is near, the robot will automatically pause operations and the operator is notified through the warning system.

Autonomous Breaker Alignment

The Breaker Racking Robot uses Laser Profilers to detect features of breakers and cabinets and autonomously align itself from up to several feet away.

Adaptable System

The robot base platform can be adapted to operate with a wide variety of circuit breaker models and improve autonomous operations.

Convenient Charging

Battery-operated and conveniently stored in the substation’s switchgear room, the robot is always ready to assist.

Integrated Safety Features

Equipped with state-of-the-art safety features and real-time alert reporting, operators can work confidently, maintaining a consistently high level of safety.

Features

- Autonomous Racking In and Breaker Removal: A combination of actuators for manipulating levers, turning the racking nut, and pushing/pulling the breaker provides automated and safe connecting and disconnecting of the breaker with the bus.

- Wireless Control Station: The robot is controlled using a control station and wireless sub-system. The graphical user interface (GUI) provides situational awareness data, real-time camera views and push button control.

- Versatile and Configurable System: The design of the base mobile platform will allow for reconfigurability to handle several types of breakers.

Where Sparks of Innovation, Meet Safety.

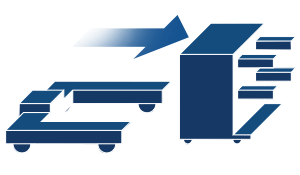

Breaker Racking Robot: Process Overview

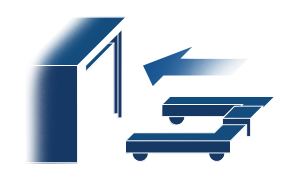

01. Autonomous Alignment

The Breaker Racking Robot utilizes 2D laser scanning and omnidirectional navigation to align itself to the breaker within the cabinet.

02. Breaker Racking Out

The breaker is racked out, lifted off the ground and secured on the frame of the robot.

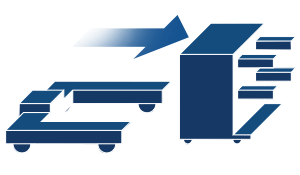

03. Breaker Storage

The robot transports the breaker to a designated storage location and picks up a Ground and Test Device.

04. Breaker Racking In

The Breaker Racking Robot autonomously aligns itself to the breaker cabinet and remotely racks the breaker or Ground and Test Device.

The Circuit Breaker Racking Robot is currently developed to handle circuit breakers (1200A, 3000A, and Ground and Test Device), but can be expanded in the future to address additional types of breakers.

More Features

- Guided Breaker Alignment: The robot uses visual aids to help operators quickly align the robot with the breaker and the cubicle for precise and repeatable lifting of the breaker off the ground and cubicle insertion and removal.

- Drive System: Mecanum wheels on the robot provide omnidirectional navigation, making it easier to move in constrained environments within power stations and provide precise alignment for autonomous operations.

- Camera Sub-System: The robot is equipped with cameras for navigation, breaker identification, monitoring the racking indicator, and alignment with the cabinet. Navigational cameras minimize blind spots and provide the operator with situational awareness.

Circuit breaker racking robot

Ready to Transform Your Substation Operation?

Connect with a ULC team member today to delve into the unique requirements of your substation and assess how the robot’s configuration can be tailored to suit your environment.

Project Partners

Con Edison

Con Edison of New York provides electric service to approximately 3.5 million customers and gas service to approximately 1.1 million customers in New York City and Westchester County. The company also provides steam service in parts of Manhattan.

ULC Technologies

ULC Technologies works with leading utility and energy companies to develop and deploy robotic systems, inspection systems, machine learning and technology that helps reduce public disruption, minimizes environmental impact and improves safety.

Related Projects

Explore Related Technologies

Autonomous Cable End Preparation & Splicing

AIM: Asset Identification & Inspection

Bombyx Fiber Installation Robot

Leading Innovation. Driving Results.

ULC Technologies develops and deploys robotic systems, smart artificial intelligence processes, and innovative inspection technology for the energy, utility, renewables and industrial sectors.

Talk to our team today: