ULC Technologies, a leader in construction robotics, has received CSO status for the development of an Unmanned Rapid Airfield Damage Repair (UM-RADR) system to perform autonomous airfield damage repair using Group IQ’s Airfield Damage Repair Kit (APR-Lite®). This prestigious status enables organizations to proceed in contracting with interested DoD partners and accelerate the adoption of advanced technical capabilities.

The unpredictable nature of humanitarian and wartime response/recovery requires military operations to rapidly adapt to unforeseen challenges. Traditional airfield damage repair methods require several construction vehicles, as well as multiple highly skilled, cross-trained teams to operate them. Deploying and maintaining such large, specialized equipment can be challenging and costly, especially in austere and remote areas.

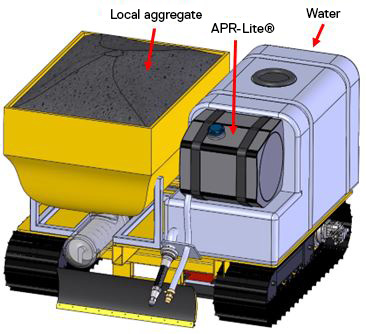

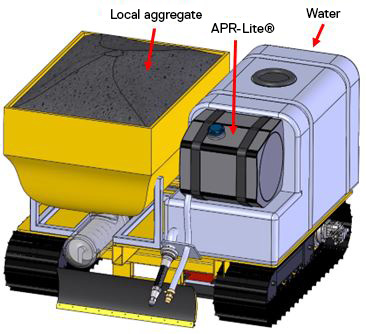

ULC was selected as a finalist for the 2024 US Air Force AFWERX Basing of the Future Showcase among over 800 total submissions. Our Unmanned Vehicle (UM) concept, Solution ID: 14706, was approved by AFCEC and deemed a vital component for the next generation of Agile Combat Employment (ACE) and Rapid Airfield Damage Recovery (RADR) technologies. To deliver increased value to warfighters, ULC partnered with Group IQ, another selected AFWERX finalist for Solution ID: 14653 – ARK APR Lite® Rapid Repair for Asphalt and Concrete, which is an advanced repair material. ARK APR-Lite® uses local water and indigenous aggregate materials to repair warehouse areas, backfill, and cap spalls. Simply described as super glue for asphalt and concrete rapid repairs, APR-Lite® is durable, easy to use, and 7-13x less expensive than current products used by the military.

“The tracked robotic solution will autonomously navigate through airfields and around any obstacles to the designated repair locations, perform a volumetric assessment of the spall size, and then carry out the repair operation,” says Mersim Redzematovic. “UM-RADR will dispense water, APR-Lite®, and local aggregate, and then compact the material in place to rapidly reinstate airfields in hostile environments.”

Automating this traditionally manual process introduces several key benefits:

- Improved soldier safety by use of robotics in hostile environments during active threats

- Multi-level remote management and monitoring of repairs

- Integration with existing UAV surveillance operations for fully automated workflows

- Reduced operational footprint enhancing agile combat capabilities (Less equipment and soldiers onsite)

- Predictable operation 24/7 through extreme weather conditions of up to 12” deep spalls

“In the proposed project, our robotic engineering team aims to develop, and field test a fully functioning RADR prototype system with an interactive command/control program,” says Redzematovic. “The Commercial Solution Opening status will allow us to rapidly move into contracting with interest DoD partners.”

ULC Technologies’ experience in the construction market displays the ability to combine cutting-edge design, complex custom software, world-class mechanical equipment, and advanced machine learning algorithms to develop revolutionary robotics and technologies to improve safety, lower costs and reduce environmental impact.

Interested in working with us? Connect with our teams to learn more about this technology and other opportunities.