- Why ULC?

- R&D Services

Research & Development

Leading Innovation. Driving Results.

- Industries

X-ID CROSS BORE DETECTION SERVICES

Our patented acoustic technology detects cross bores from within gas mains and services. Learn MoreLIVE GAS MAIN INSPECTION

We are leaders in the deployment of camera and crawler systems into live gas mains. Learn More

PORTABLE EMISSIONS RECOVERY

Our drawdown compressor technology helps gas distribution utilities reduce emissions. Learn More

AIM: AI-POWERED UTILITY MAPPING

Using vehicle-mounted cameras along with AI and Machine Learning to map electric distribution poles and pole-mounted assets. Learn More

CIRCUIT BREAKER RACKING ROBOT

Breaker Racking RobotAutonomous mobile robot designed to rack and unrack large breakers within substations. Learn More

ELECTRIC CONDUIT INSPECTION

Our field service teams provide video inspection of conduits prior to cable pulls to identify obstructions and pinpoint damages. Learn More

Machine Learning for Jacket Foundation Inspection

ULC used machine learning to enable more efficient inspection of jacket foundations at the Block Island Wind Farm. Learn More

Electrical Conduit Inspection Services

Our field teams provide internal inspection of conduits to pinpoint obstruction and damage prior to cable pulls. Learn More

Robotics & Technology Development

We work with leading energy companies to develop, commercialize, and deploy robotic systems and technologies that support the construction, maintenance, and inspection of infrastructure. Learn More

ROBOTIC GPR MAPPING AND MARK OUT

AUSMOS is an autonomous robotic platform that detects and marks-out below-ground infrastructure using sensors. Learn More

VEST: VACUUM EXCAVATION SUPERSONIC TECHNOLOGY

VEST improves the performance of vacuum excavation by integrating supersonic air nozzles into the vac-ex tool head. Learn More

UM-RADR: UNMANNED RAPID AIRFIELD DAMAGE REPAIR

Robotic platform is deployed to damaged airfields to remotely perform repairs. UM-RADR qualifies for Commercial Solution Opening (CSO) status. Learn More

- Products & Services

Field Services

Products

Live Gas Main Inspection Cameras

Emissions Recovery

- Company

Electric Cable End Preparation System

Home > Technologies > Electric Cable End Preparation Machine

TECHNOLOGY

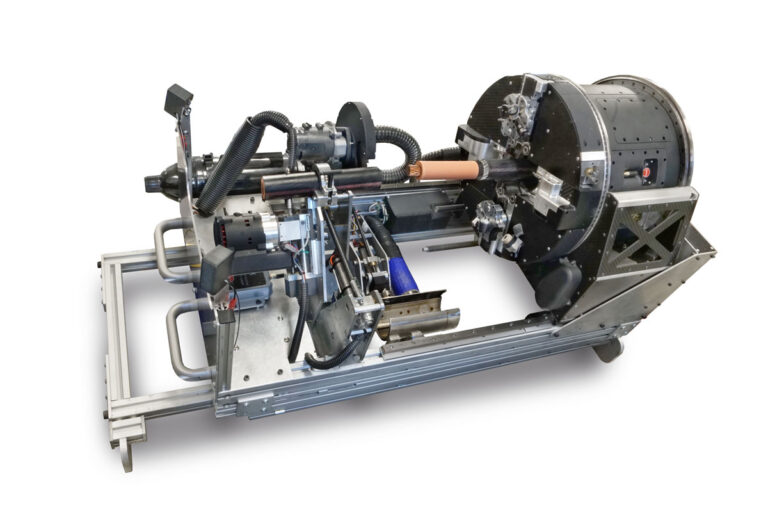

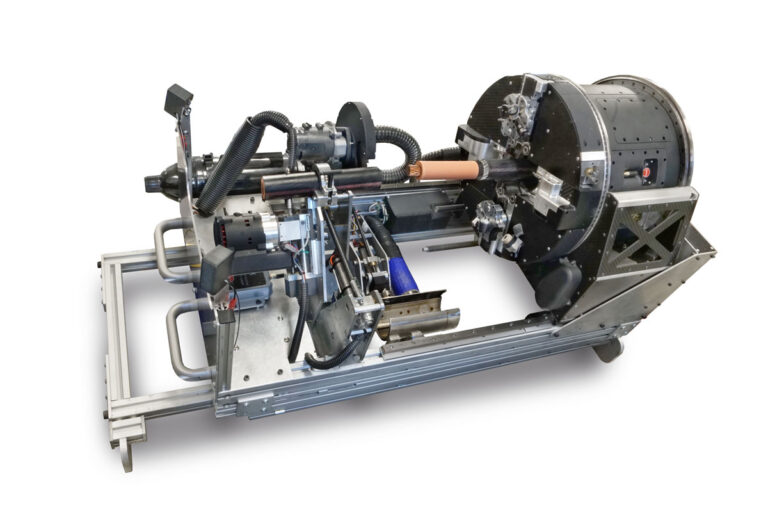

Medium Voltage Electric Cable End Preparation System

ULC Technologies and Con Edison Company of New York have developed a machine that automates the preparation of medium voltage cables for termination, enabling more reliable and resilient connections within the power grid while improving the safety of utility workers.

This machine will allow operators to improve the repeatability and consistency of critical connections within the electric grid by automating cable end preparation and minimize their exposure to high voltages.

Key Benefits

Enhanced Operator Safety

Prioritize safety and mitigate risk by relocating operators away from potentially hazardous situations, especially when working with medium voltage lines, drastically reducing the potential for operator errors.

Improved Operational Efficiency

Tackle time-consuming tasks that otherwise demand considerable manual effort from human operators, significantly improving efficiency, while ensuring a more streamlined workflow.

Repeatability and Consistency

The machine’s precision and repeatability across each step of the operation consistently deliver high-quality results, enhancing the overall reliability of the process by eliminating human bias.

Cost-Effective Operation

Automation reduces the need for labor-intensive procedures, saving both time and money. Additionally, the reduction in human errors minimize the risk of costly repair or replacement of damaged equipment

Time-Sensitive Responsiveness

Efficiency and rapid execution are invaluable during emergencies and maintenance work, ensuring that power outages are minimized and utility services can be restored promptly.

Compact Machine Size

The Cable Splicing Machine is designed to be installed in a crowded manhole and was developed to avoid interference with other cables and structures in the vault.

Cable Splicing Machine Functions

How It Works

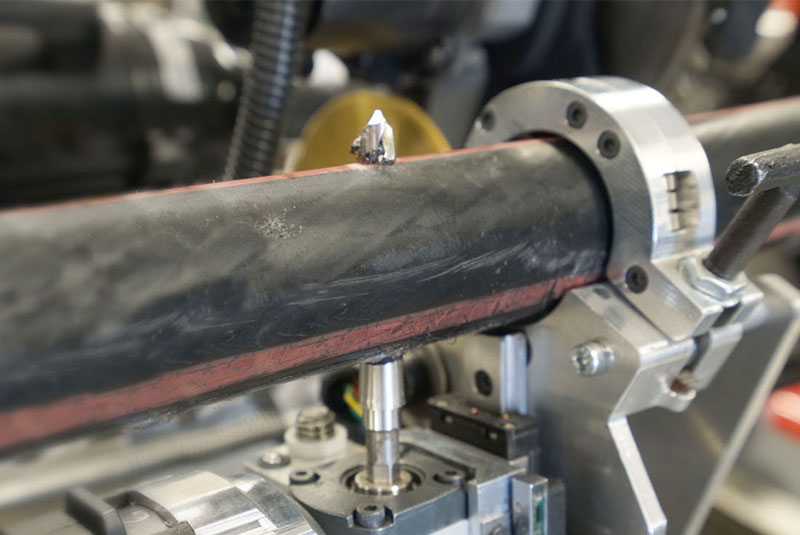

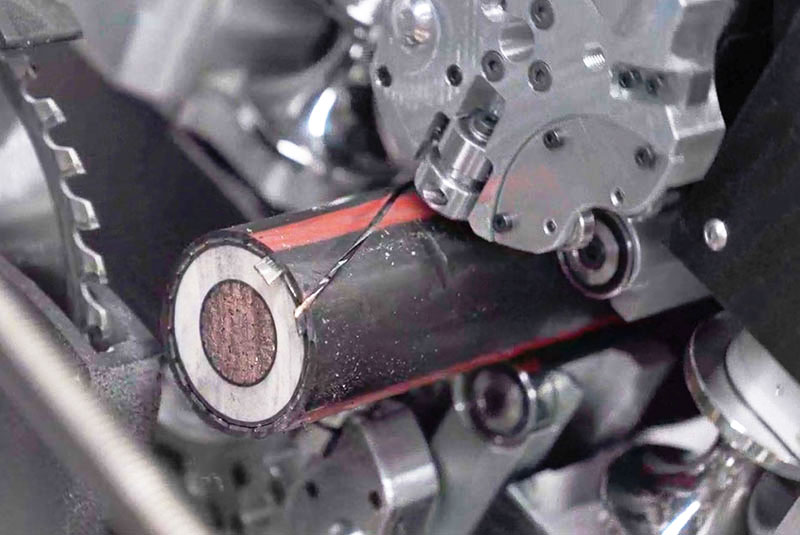

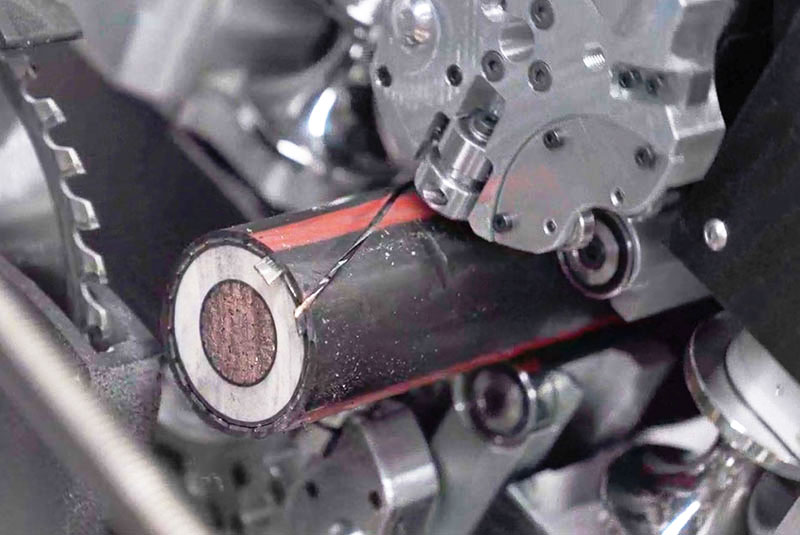

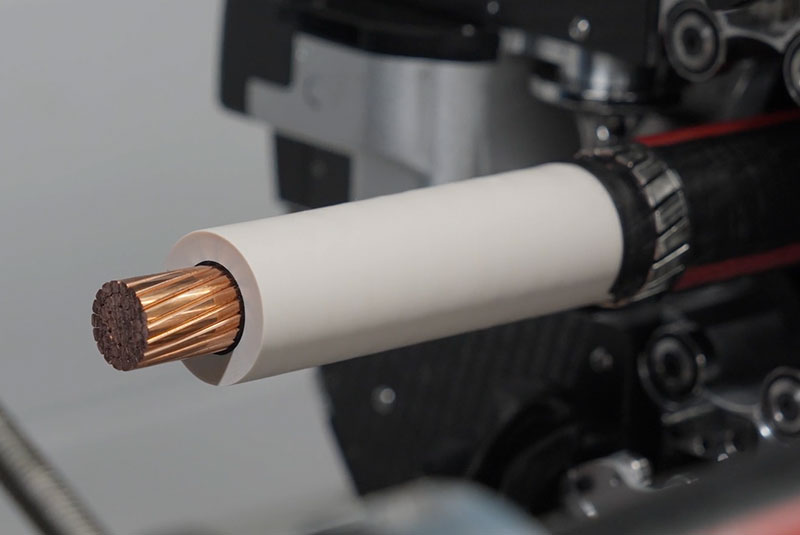

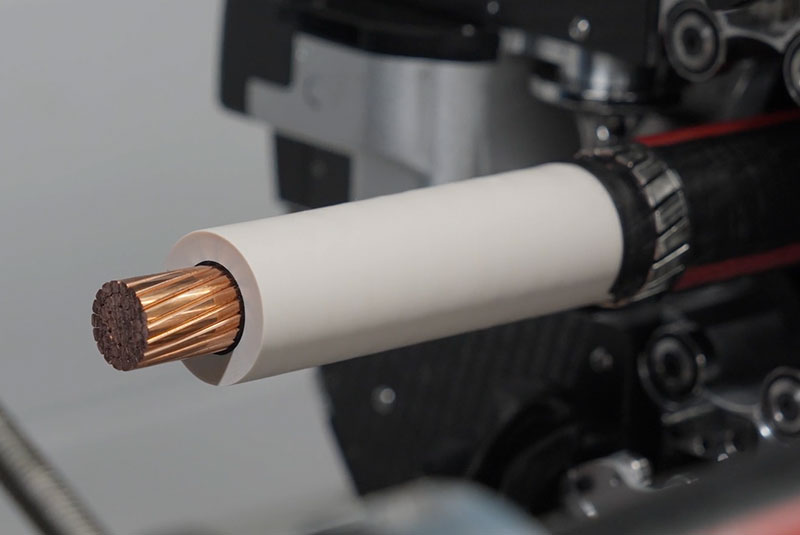

The Cable Splicing Machine is secured onto the middle of an uncut cable in the field and uses electrical actuators to provide precise coordinated motion along the axial and circumferential directions, including continuous 360-degree operation. The machine’s tool plate consists of numerous tools capable of stripping back each layer of the cable to a desired dimension using precision tool depth controls. Future developments will aim to expand the types of splicing operations that the machine will be capable of performing.

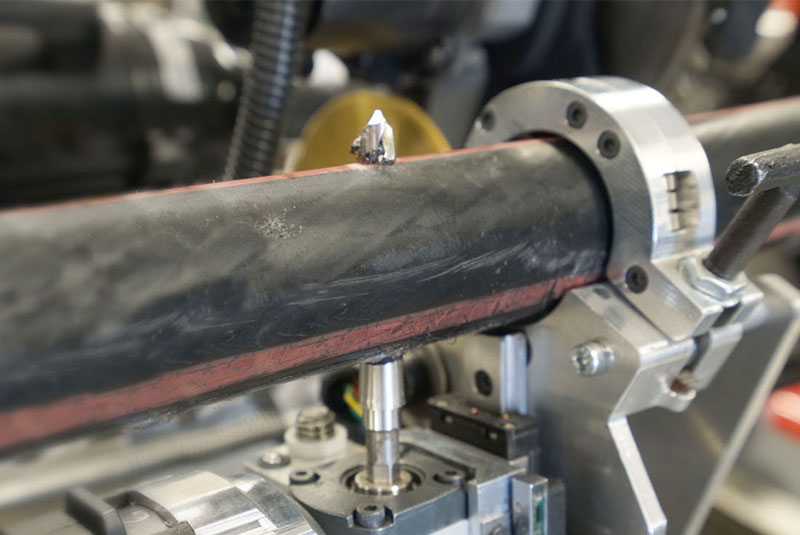

Shorting

A precision drill ensures a robust connection between the cable’s conductor and the grounding straps. This connection is essential for minimizing potential hazards.

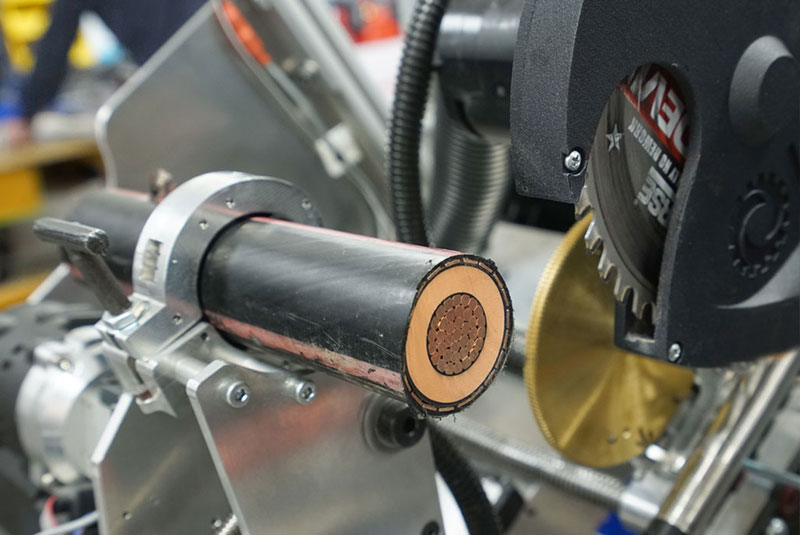

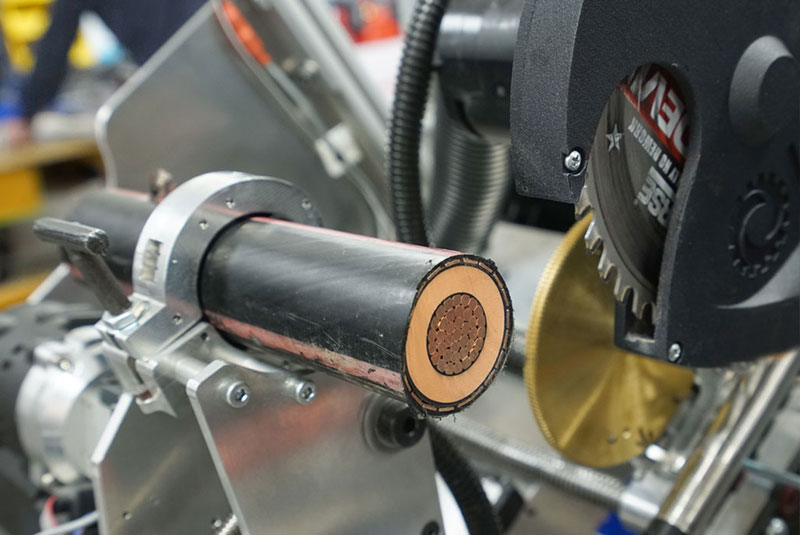

Cutting

Autonomously cut the cable to the required length. This is the initial step in readying the cable end for end prep and seamless integration into the splice or end cap assembly.

Jacket Removal

Carefully strip away the cable’s outer protective layer, revealing the underlying components. This step is pivotal for accessing the cable’s core and is autonomously executed by the machine.

Insulation Removal

Remove the insulating material from the end of the cable. This crucial operation exposes the cable’s core, providing a clean point of connection for a successful splice.

Semicon Removal

A proprietary technique for the removal of the layer surrounding the insulation achieves the complete and clean removal of the outer semiconductor layer ensuring optimal cable integrity.

Prepped for Splicing and Termination

Now that each layer of the cable has been stripped back to the desired dimension, it is ready for splicing or termination. Future developments of the Cable Splicing Machine will aim to expand the types of operations the machine will perform.

Have a question?

Connect with our engineering team to learn more about the Cable Splicing Machine or to discuss bespoke cable end preparation solutions.

Project Partners

Con Edison

Con Edison of New York provides electric service to approximately 3.5 million customers and gas service to approximately 1.1 million customers in New York City and Westchester County. The company also provides steam service in parts of Manhattan.

ULC Technologies

ULC Technologies works with leading utility and energy companies to develop and deploy robotic systems, inspection systems, machine learning and technology that helps reduce public disruption, minimizes environmental impact and improves safety.

“Worker safety is paramount. The technology used in this tool will enable our workers to splice high-voltage cables, efficiently, uniformly, and most importantly more safely. When you reduce the risk of performing thousands of splices each year and improve their accuracy and efficiency, it benefits workers, grid reliability, cost-effectiveness, and value. That’s a win, win, win for Con Edison, its workers, customers, and the industry.”

- Patrick McHugh, Senior Vice President, Con Edison Electric Operations

Your Partner in Innovation

Join us in revolutionizing cable splicing and underground vault operations by deploying and testing our cutting-edge machine in the field.

Reach out to us today and be part of the future of safer, more efficient utility services. Together, we can make a substantial impact on the industry’s operational excellence.

Related Projects

Explore What We've Done

|