- Why ULC?

- R&D Services

Research & Development

Leading Innovation. Driving Results.

- Industries

X-ID CROSS BORE DETECTION SERVICES

Our patented acoustic technology detects cross bores from within gas mains and services. Learn MoreLIVE GAS MAIN INSPECTION

We are leaders in the deployment of camera and crawler systems into live gas mains. Learn More

PORTABLE EMISSIONS RECOVERY

Our drawdown compressor technology helps gas distribution utilities reduce emissions. Learn More

AIM: AI-POWERED UTILITY MAPPING

Using vehicle-mounted cameras along with AI and Machine Learning to map electric distribution poles and pole-mounted assets. Learn More

CIRCUIT BREAKER RACKING ROBOT

Breaker Racking RobotAutonomous mobile robot designed to rack and unrack large breakers within substations. Learn More

ELECTRIC CONDUIT INSPECTION

Our field service teams provide video inspection of conduits prior to cable pulls to identify obstructions and pinpoint damages. Learn More

Machine Learning for Jacket Foundation Inspection

ULC used machine learning to enable more efficient inspection of jacket foundations at the Block Island Wind Farm. Learn More

Electrical Conduit Inspection Services

Our field teams provide internal inspection of conduits to pinpoint obstruction and damage prior to cable pulls. Learn More

Robotics & Technology Development

We work with leading energy companies to develop, commercialize, and deploy robotic systems and technologies that support the construction, maintenance, and inspection of infrastructure. Learn More

ROBOTIC GPR MAPPING AND MARK OUT

AUSMOS is an autonomous robotic platform that detects and marks-out below-ground infrastructure using sensors. Learn More

AIRPULSE: VACUUM EXCAVATION TECHNOLOGY

AirPulse improves the performance of vacuum excavation operations by integrating supersonic air nozzles into the head of the vacuum hose. Learn More

UM-RADR: UNMANNED RAPID AIRFIELD DAMAGE REPAIR

Robotic platform is deployed to damaged airfields to remotely perform repairs. UM-RADR qualifies for Commercial Solution Opening (CSO) status. Learn More

- Products & Services

Field Services

- Company

Unmanned Rapid

Airfield Damage Repair

Home > Technologies > Rapid Airfield Damage Repair

Technologies

Improved Soldier Safety with Autonomous Airfield Damage Repair

The unpredictable nature of humanitarian and wartime response/recovery requires military operations to rapidly adapt to unforeseen challenges. Traditional airfield damage repair methods require several construction vehicles, as well as multiple highly skilled, cross-trained teams to operate them. Deploying and maintaining such large, specialized equipment can be challenging and costly, especially in austere and remote areas.

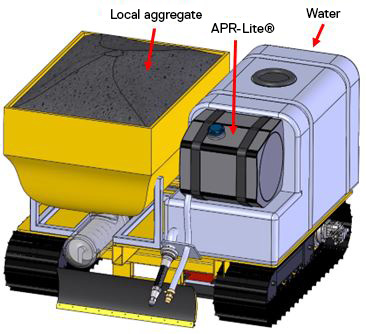

ULC Technologies has developed an Unmanned Rapid Airfield Damage Repair (UM-RADR) platform, capable of performing autonomous airfield damage repair using APR-Lite®. This tracked robotic solution will improve airfield personnel safety and increase repair operation efficiency overall.

In accordance with DFARS 212.70, the UM-RADR concept qualifies for Commercial Solution Opening (CSO) status and is eligible to proceed into contracting with interested DoD partners.

Key Benefits

Enhanced Safety

Increased Efficiency

The deployment of robotics reduces the operational footprint, enhancing agile combat capabilities with less equipment and personnel on-site.

Reliability

RADR provides predictable and reliable operation 24/7, even through extreme weather conditions.

Remote Management

This system offers multi-level remote management and monitoring of repair operations.

Workflow Integration

RADR can be easily integrated with existing UAV surveillance operations, enabling a fully automated workflow.

Rapid Airfield Damage Repair

How It Works

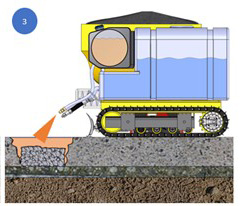

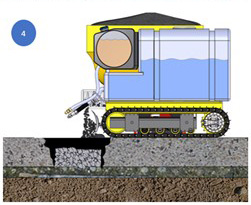

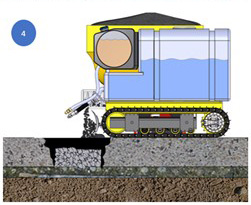

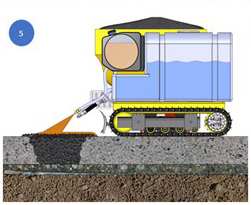

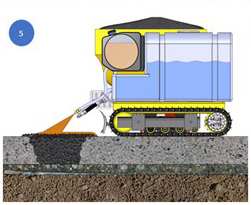

Once the damage assessment is completed (through UAS solutions or survey) the UM-RADR system autonomously navigates past any obstacles to the programmed coordinates of the designated spalls and performs a volumetric assessment of the spall size before beginning the autonomous refill and repair operation. The figures below depict each step in the refill and repair operation:

Step 1:

Debris is pushed into the spall

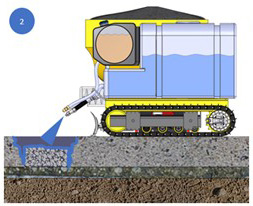

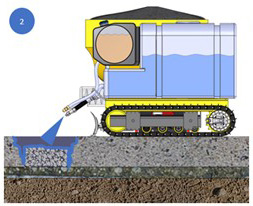

Step 2:

The spall is then coated with water

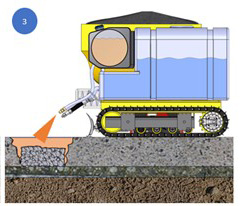

Step 3:

RADR then applies APR-Lite® to the spall

Step 4:

Apply 2-inch lift with local aggregate

Step 5:

Second round of APR-Lite® is then applied

Step 6:

Lastly, tamp area and allow to cure

What is APR-Lite®?

Both selected for the US Air Force AFWERX Basing of the Future 2024 Showcase, ULC collaborated with Group IQ and their APR-Lite® solution. APR-Lite® uses local water and indigenous aggregate materials to repair warehouse areas, backfill, and cap spalls. It’s a 3-step smart liquid used to rejuvenate damaged areas, precondition the surface, and last as a permanent binder.

- It’s a Super Glue for asphalt and concrete rapid repairs

- It’s durable, easy to use, and 7-13x less expensive than current products used by the military

- When combined with water and local aggregate fillers, it’s ideal for remote and austere locations, staging areas on unimproved dirt or gravel surfaces

In accordance with DFARS 212.70, the UM-RADR concept qualifies for Commercial Solution Opening (CSO) status.

Interested in working with us? Connect with our team to learn more about this technology and other opportunities.

Project Partners

ULC Technologies

ULC Technologies works with leading utility and energy companies to develop and deploy robotic systems, inspection systems, machine learning and technology that helps reduce public disruption, minimizes environmental impact and improves safety.

Group IQ

Group IQ LLC aims to create a safer and better community by cost-effectively improving the quality of repairs on streets and other public areas with the invention and manufacturing of Advanced Preservation & Repair (APR®) products for asphalt and concrete maintenance. They have a global headquarters in California, with manufacturing facilities in the Midwest and field offices in the US, Europe, Asia, and Africa.

Leading Innovation. Driving Results.

ULC Technologies develops and deploys robotic systems, smart artificial intelligence processes, and innovative inspection technology for the energy, utility, renewables and industrial sectors.

Talk to our team today: